Plastics were used for almost everything in this century. Specially because of its low cost of production, among other many things. Flexibility and easy acceptation from society were also the key for this success.

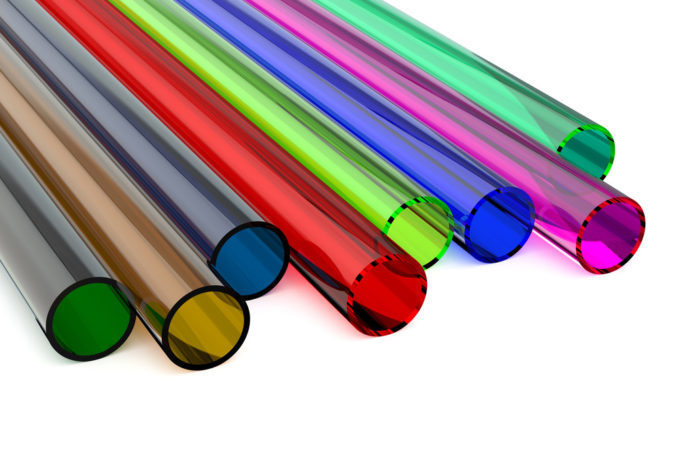

It is curious that producing plastic is possible replace some classic materials like leather, paper, transparent and translucent glass ,even with pigmentation. Also some stones and recently and inexplicably human skin.

BASF, Dupond, Poligal and Sika are recognized companies involved with plastic manufacture. Technically there are three group of them, thermoplastics, woodplastic and thermosets. However, there is other types of plastic’s classification like density.

Different Types of Plastics

1. Thermoplastics

Are shaped by heat, their physical properties change gradually. There are different systems like injection and molded.

For some companies, the versatility of thermoplastics by reshaping, is primordial for producing unique pieces. Polystyrene is a example and the German company BASF with Dupong are a couple of the leading productors in the world.

2. Woodplastic

Nowadays, this develop allows create this unique kind of plastic by mixing in factories wood fiber and PE, PP and PVC. Also, other additives are used, but just a bit is good enough to keep the plastic’s properties.

In the market, this product is present in items for constructions, replacing other materials more expensive. The main use in the last couples of years was in windows, benches and some custom door frames, being and inexpensive option in counties like UK and United States.

3. Thermosets

Unfortunately is not possible change the shape after heating. After producing this sort of plastic, they stay solid. For this reason, the way of production is necessarily different. Thermosets epoxy resins and polyester are clear examples.

In the last couple of years, the leading German and American companies in this industries had developed improvements for some specific products of high value in industries like aircrarfting.